TMM4175 Polymer Composites

About¶

Jump to: Detailed content | Assignments and assessment | Schedule Spring 2022 |

TMM4175 Polymer Composites is a NTNU graduate course for mechanical engineering and material science students. Recommended and expected previous knowledge includes Mechanics corresponding to TKT4116 and TKT4122 as well as basic materials technology such as TMM4100.

As the name suggests, the focus is on polymer matrix composites. The composites made of glass, carbon and aramid fibers embedded in thermoset and thermoplastic matrices including epoxy, polyester, polyamide and polypropylene play important roles in a wide range of industries, from sport and leisure products to automotive, boats and aerospace solutions.

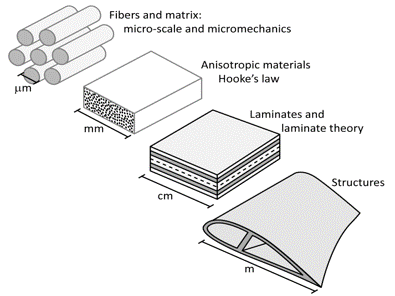

TMM4175 has a multiscale approach where the fundamental mechanisms on the microscale is the basis for understanding the behavior on the material’s macroscale. Constitutive relations of materials combined with laminate theory enables a practical and efficient framework for composite engineering and design of components and structures.

The anisotropic nature of composite materials implies that there are many material constants and orientations involved. Furthermore, composites are often found as layered structures (laminates). These laminates may have a high number of layers. Consequently, efficient numerical studies on composites and laminates requires numerical tools to handle the evaluations of a large number of expressions, particularly linear algebra and matrix operations. In TMM4175 Polymer Composites, we use Python and relevant Python libraries and modules as the primary tool for developing numerical procedures, as well as for visualizing results and illustrating examples.

Detailed content¶

The online compendium (Table of contents) follows the outline of typical textbooks on composite materials and design/engineering with the following main sections:

- Composite Materials: An introduction to composites in general and common classifications, overview of common fibers and polymer matrices, geometrical aspects and composition in terms of mass and volume fraction of the constituent materials.

- Mechanics of Materials: Definitions and applications of stress, strain, Hooke’s law, thermal expansion, transformations, micro-mechanical models, interaction between fibers and matrix and a brief outline of relevant topics regarding viscoelastic and plastic behavior.

- Strength and Failure Theories: Basic definition of strength and strength parameters, principles of failure prediction, failure criteria including maximum stress, maximum strain, Tsai-Wu Hashin and Puck.

- Laminates and Laminate Theory: Terms and definitions, assumptions, plane stress and plane stress failure theories, laminate loads, deformation and constitutive relations, computational procedures, features of laminate types, thermal effects, effective properties interlaminar failure and progressive damage analysis

- Finite element analysis: Introduction to FEA and Abaqus, material models and material orientation, relevant solid and shell elements, layered structures and failure prediction of layered shell elements.

- Test methods: Overview of test methods including tensile and compressive testing, shear testing, biaxial testing and interlaminar fracture mechanical testing

- Manufacturing: Common processing steps from fibers and matrix to composites components

- Engineering and reliability: Standards and guidelines for polymer composites, safety factors and material variability.

The philosophy of the compendium extends however beyond regular textbooks as it provides a comprehensive set of ready-made codes and numerical examples for theories and computational procedures. These codes and examples can easily be adapted to student’s own work.

It did not make much sense to write just another textbook about composites.Herakovich, Daniel and Ishai, Jones, Hull, Reddy, Tsai and many others have all made excellent contributions to the composite materials section of the library. Also worth mentioning particularly is the textbook Mechanics of Composites Materials with MATLAB by Voyiadjis Kattan, where the theories for the mechanics of composites are supported with MATLAB codes. The pedagogical literature do indeed suggest that a skillset is obtained by applying and implementing the theory.

While MATLAB is an excellent tool, it does not seem to have an extensive use outside the academic institutions. The current trend at NTNU is a major transition from MATLAB to PYTHON in both introductory courses and in applied engineering courses. When sorting out the status, available resources and identifying the needs, the following specification for a compendium in Polymer Composites was made:

Working title: Composites with Python, Not a traditional textbook, and Online with embedded codes and examples.

The compendium was made using Jupyter Notebook with Python 3.x.

Assignments and assessment¶

Portfolio assessment is the basis for the grade in the course. The portfolio includes a final written exam (50%) and project works (50%). The results for the parts are given in %-scores, while the entire portfolio is assigned a letter grade.

The project works shall preferably be group based. Individual exceptions and custom arrangements can however be made for reasonably valid circumstances.

Each group is expected to submit five assignments where the groups can chose among a few different problem descriptions for each assignment. The problems span from literature review to numerical methods, FEA and engineering.

Assignments (examples)¶

- Properties and applications of common thermosets for polymer matrix composites

- Properties, state of art and future trends for natural fibers for structural composites

- Micro-mechanical finite element models

- Implementation of computational procedures for general transformation of stresses, strains and elastic properties

- Failure assessment of a thick walled carbon fiber composite pipe

- Free edge effects of laminates

- Stiffness and strength optimization of composite panels

- Optimization of a pressure vessel

- Experimental: flexural testing of laminated beams

- Experimental: DCB and ENF testing

- Experimental: tensile-twist coupling

- Engineering of a composite component/structure using FEA, standards and guidelines)

Schedule Spring 2023¶

Please find the detailed schedule on Blackboard.

Disclaimer:This site is about polymer composites, designed for educational purposes. Consumption and use of any sort & kind is solely at your own risk.

Fair use: I spent some time making all the pages, and even the figures and illustrations are my own creations. Obviously, you may steal whatever you find useful here, but please show decency and give some acknowledgment if or when copying. Thanks! Contact me: nils.p.vedvik@ntnu.no www.ntnu.edu/employees/nils.p.vedvik

Copyright 2021, All right reserved, I guess.